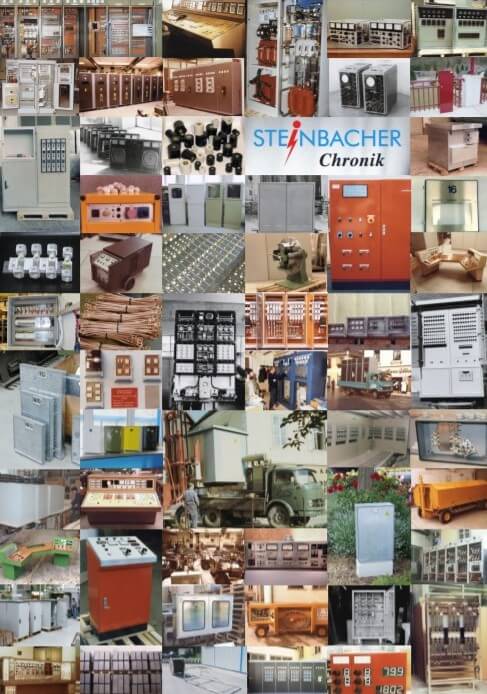

Where do we come from? Where does our path lead?

Future needs background. Embark on the search for clues in our detailed Company History.

Impact of the pandemic

The worldwide Covid 19 crisis situation and the associated delivery bottlenecks, staff shortages and price increases are also placing particular demands on the Steinbacher team. However, thanks to investments made in the past, high flexibility and a large stock, the company always remains able to deliver. We are also taking the current developments as an opportunity to devote more attention to the area of digitalisation and to link our ERP system with a web shop.

Farewell

We bid farewell to Ing. Anton Steinbacher (23.9.1928 - 7.5.2017), who shaped the company with his pioneering spirit and was active in the company until the very end.

Ready for 5G

We are expanding our product range with microtubes for fiber optic cables, shafts and components for broadband expansion. We achieve record sales thanks to our diverse product range, expansion and optimization of storage capacities.

Site concentration

At the Wieden site a 2000 m² new production hall and an associated office building are built. The planning and construction coordination takes place in-house. In 2015 the relocation can be completed. In the old building in the village the electroplating is still in operation, the premises serve as a warehouse and archive.

New customers and product development

We win many new customers and can deliver promptly through our unusually large warehouse. New developments for Asfinag such as access point cabinets, OpenWis winter service slipperiness detection systems, fuel cell cabinets with solar panels and IR-checkpoints enable us to enter the market in new areas.

Extension of wholesale assortment

Increased involvement in the expansion of the wholesale program and the acquisition of various agencies result in a 40% increase in sales. New product groups in the field of distribution of electrical energy such as chandeliers, lightning protection and overhead line material or tools such as pull-in systems contribute to the success. In-house developments for example plaster frames for full thermal insulation are attracting interest.

Stroke of fate and appeals to stand firm

The cancer disease of Julia Steinbacher (1990-2002) to change the Millennium burdened the commitment in the company and put expansion plans on hold. Three-year struggle with chemos, many operations, liver transplantation by living donation from the father bring no lasting success.

Computer networking in all areas

In 1998 the old residential building dating from 1894 was completely renovated and integrated into the company premises. One year later the new ERP system ProAlpha is introduced. International trade fair participations including Göteborg, Hannover, Prague, Munich and Vienna increase our profile in the market.

First cut of the spade at Wieden

On 1.6.1995 after the acquisition of the 30,000 m² site on the outskirts, the groundbreaking ceremony for a new production site can take place. One year later on 1.6.1996 hall 1 with an area of 2500 m² is put into operation and the work in the areas of sheet metal working, plastic injection molding and tool making can be started.

Setting the course

This year the acquisition of the company shares of the family Schweighofer by family Steinbacher and the purchase of a 3-hectare site outside the village take place. The company now operates under the name Steinbacher Energie. At the same time we are successfully completing the ISO 9001 qualification procedure, making us one of the first 300 companies in Austria to have this certificate.

3rd generation change

Ing. Helmut and Ing. Martina Steinbacher take over the management and organize the processes with the introduction of a computerized system. Illustrated product catalogs are improved and professional marketing is built up. Ing. Anton Steinbacher sen. continues to lead the technical departement. At the end of 1988 the location Dorf was extended by the installation of a final assembly for the booming KVS business.

New products and sales network development

Ing. Helmut Steinbacher is increasingly dedicated to sales agendas and draws first sales experience in the marketing of the in-house developed tennis ball throwing machine Serviceboy. In the long term we focus on the core business of distributors and special equipment: electrical equipment for cable cars (Schlossalm, Grießenkareck, Rüfikopf, Kanzelwand ...), electricians for snowmaking systems, power plant technology, switch cabinets for a Schmitz reversing mill (2500 kVA) with thyristor feeders, switchgear for a fully automated 550kVA small power plant, temperature controls for gas pipeline Siberia-Germany and so on.

Stroke of fate for Schweighofer family

Ing. Franz Schweighofer (1932-1983) died unexpectedly in 1983 and Ing. Helmut Steinbacher takes over his sales agendas. His wife Eleonore (1925-1995) retires and does the accounting. Widow and daughter remain as shareholders. The Seniors Steinbacher try to compensate for the loss.

Start-up production in a wide variety

Meanwhile there is a wide range of products with a broad customer base: electrical equipment for iron and steel industry such as 10 MVA power station, electron beam welding machines, shuttle kilns, bell annealers, stranding machines, aircraft test stands, frequency and DC converters, tropical-type starting units, Oscilloscopes, custom printed circuit boards, row and tool cabinets, garden furniture and much more.

Expansion of family seat to production site

The newly acquired neighboring property is used to build offices, a detail shop and a production hall. Plastic coating and electroplating are established as new processes. We celebrate the 50th anniversary as an independent electrician with 40 employees in a family structure.

2nd generation change - product development of distribution cabinets

Ing. Anton Steinbacher jun. builds high-tech facilities such as aircraft test benches and begins manufacturing cable distribution cabinets. In 1963 he takes over the company with his wife Ottilie (1928), his sister Eleonore and their spouse Ing. Franz Schweighofer. The core business is shifting from electrical installation and repair business to a diversified manufacturing company.

World Economic Crisis and World War II

Innovative from the beginning Anton Steinbacher sen. pushes on with the electrification and mechanization of the entire region. A rigid policy of cutbacks and flexible business dealings in the electronics area and repair services enable the family to secure a living and train the three children in the areas of technology and business.

Company foundation electrical engineering

In 1914 the sons Friedrich, master builder (1887-1971), and Anton Steinbacher, master mechanic (1891 - 1966), joined the company and employ 45 people. In 1921 the field of electrical engineering (= today's Steinbacher Energie GmbH) splits off and is run as an independent company in Dorf 8 ("Haus an der Brucken", built in 1648).

Founding steam sawmill and electric plant

Michael Steinbacher (1864 - 1931) founds a carpentry company with a construction business and steam sawmill in Hollenstein an der Ybbs am Zimmerplatz. In 1907 and 1908 he secured the light and power supply of Großhollenstein by means of two dynamos of 8 kW DC with 230 V.